VACUUM PUMPS

section-e9a4d85

Description & Specifications

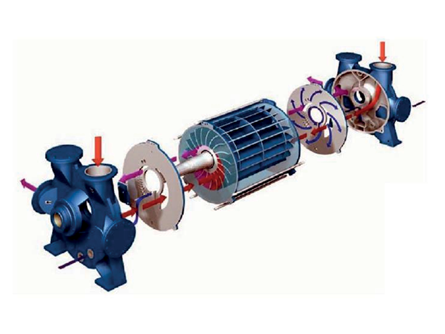

- Specially designed tapered double-row roller bearings, design life 200 000 hours, reliable operation.

- Redesigned impeller stiffening rib, optimized blade force regime, effectively prevents accumulation of dirt or impurities, which results in no energy consumption increase during pump operation.

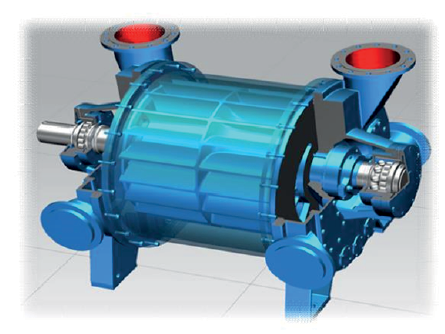

- Choice of inlet and outlet ports on top and sides, more convenient piping technology.

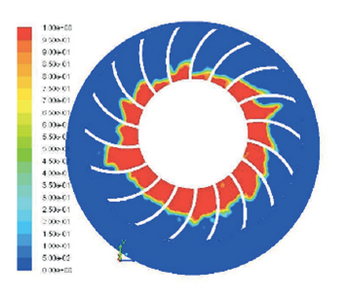

- The design efficiency has been significantly improved, the impeller blades have redesigned the flow lines and improved the hydrodynamic calculation, the design of the circular disc and the end cover has been improved as well, resulting in better flow channels, increased efficiency and reduced energy consumption by 10-20% compared to other products.

- The distinctive part of the pump is the impeller. Quality of impeller manufacturing is controlled repeatedly, use of bearings from leading manufacturers, selection of high-strength materials - all this ensures lifetime of the pump. Material of impeller is high quality sheet steel, blades are stamped once, wheel hub is processed inside and outside. Welded manufacturing technique is used and the whole unit is annealed. Good balancing: the issue of dynamic balancing is solved. It has the following features: high strength, wear resistance, never breaks, has shock resistance properties, meets advanced international standards.

- The impeller and pump shaft have a hot keyless interference fit. This prevents loosening, which can be caused by the keyed connection. The impeller and shaft are precision machined on both ends and the balance of the impeller is guaranteed. Before installation the impeller is coated again with a special anti-corrosion material to increase wear and corrosion resistance. Stable performance and reliable efficiency.

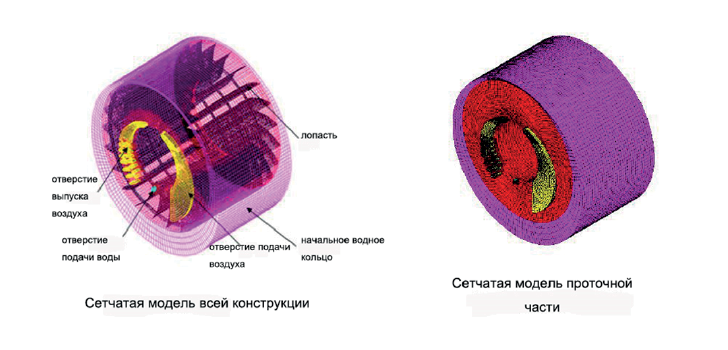

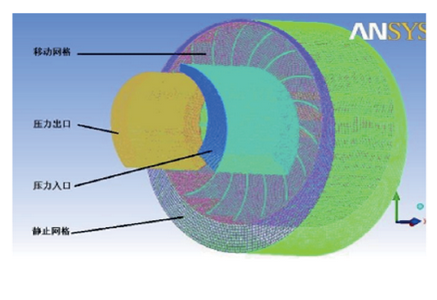

- Through CFD analysis of the flow field and calculation of the best discharge angle of the impeller blades, the flow velocity of the circulating fluid is increased, the space and volume of suction air is increased as well.

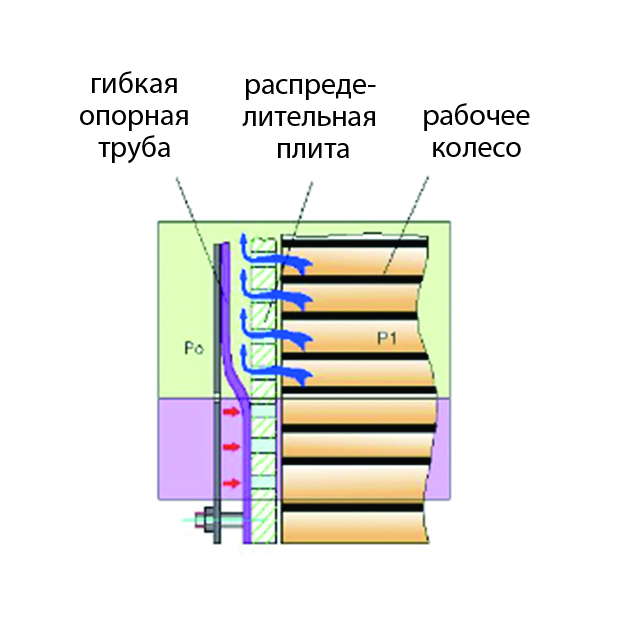

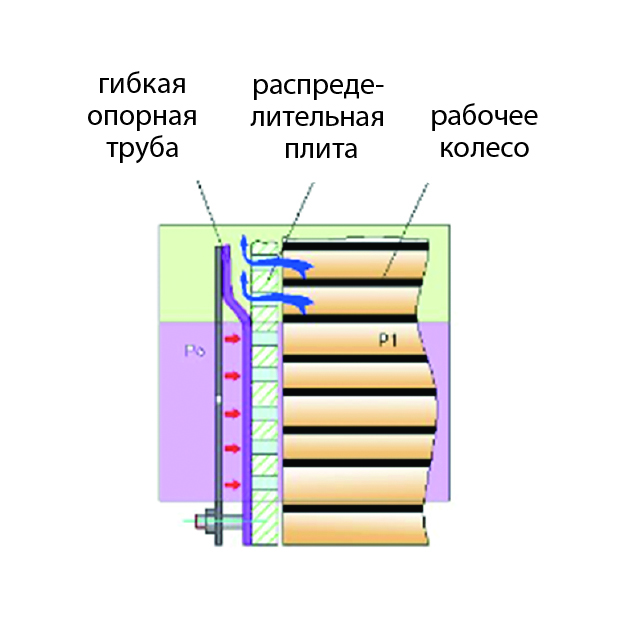

- The flexible plastic design of the air outlet ensures that the entire vacuum space remains highly efficient. With the change of the intake air pressure, the outlet air pressure can be automatically adjusted, over-compression of the air is prevented, thus guaranteeing the stability of the system and greatly reducing the power consumption.

- Shaft sleeves are applied. The material of the sleeves is 304 steel, resistant to wear and corrosion, which allows the shaft to avoid any damage. Maintenance costs are thereby reduced.

- Each pump cover has two inspection hatches through which the valve plate inside the pump can be viewed and repaired without completely disassembling the pump.

Dynamic distribution of water and air inside the pump during operation

Settings for boundary conditions inside the pump during operation

- CFD can analyze the flow field and calculate the inspection, improved design of air inlet/outlet angle and distribution plate area, discover the best combination of air inlet angle and air inlet/outlet area, increase the air pumping volume.

- The main part of the vacuum pump is the distribution plate, which is made on a digitally controlled water-jet cutting machine. Cold cutting technology is used where there is no thermal deformation. This technology prevents physical and chemical changes that can destroy the material. The control of digitally controlled system allows to achieve high precision cutting, high tolerance level, improved design of the theoretical drawing line of the distribution plate. And also improve the divert effect, increase the suction/discharge area, improve the vacuum pump efficiency.

at a low compression ratio

at high compression ratio